Swinging for the fences

- Updated: November 1, 2015

Cherokee County father-son team turning basement hobby into fledgling wood bat business

Father and son Mark (R) and Cade Gossett have turned a hobby in the basement into a bat production business.

By Al Muskewitz

East Alabama Sports Today

CENTRE – Mark Gossett didn’t intend to turn the family hobby into a business, but sometimes it just makes sense.

Gossett and his son Cade have been turning out baseball bats from their basement the way golfers build their own clubs for several years, but three months ago they took it to the next level and the Cherokee Bat Company was born.

Working under the motto “swing big, dream big” they hope their bats become a big hit among local players and maybe find a niche all the way up to the big leagues.

Actually, the business has roots in necessity. They simply tired of buying new wood bats to replace the ones Cade was breaking in practice.

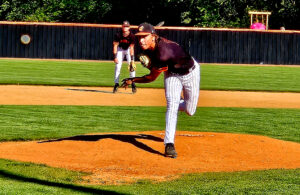

“I broke a lot of bats,” said Cade, a junior who plays multiple positions for the Cherokee County High School baseball team, “and we just kind of thought it’d be fun to make our own and easier that way.”

They figure they’ve replaced about two dozen bats from the time Cade started playing as an 8-year-old. The last straw came three months ago when he broke a beloved $200 Troy Tulowitzki model that served him well in a travel-team tournament just a week earlier.

“When that one broke, we were just sick,” Mark said. “We had been kicking around the idea about a year and we thought then we might as well give it a try. We decided if we’d make a few for him to use maybe we could for others. We just love baseball and always have. We absolutely enjoy it.”

The majority of their bats are maple, but they also work in the more traditional ash. They get the bats pre-spun and dried from an approved company in Tennessee, then hand-finish the handle and barrel, cup the end, rub the whole thing down with deer antler and apply the color.

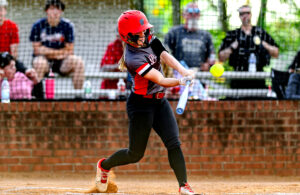

The bats they’ve made so far are 32, 33, 33.5 and 34 inches, and they’ve just recently started making fungoes. The bats sell for $70 and come in a variety of colors and finishes. Some even have been done in school colors.

They’ve sold about a dozen so far, but are expecting an influx of orders in time for Christmas and as word circulates anticipate business to pick up closer to the spring.

“That bone rubbing seems to be something that’s gone on from beginning of wood bats; some people think there’s some validity to it,” Mark said. “It does seem to bring out the grain and makes it a little more dense.”

The secret to a good bat is strong grain and precise balance; the rest falls to individual preference.

Sometimes the finishing process yields surprises. Like the time Gossett was cupping the end of an ash bat and uncovered a shard of metal in the wood. Further digging revealed a lead bullet.

The fragment wasn’t in too deep and they were able to continue the process without sending the bat to the scrap pile. Approved bats can have no voids or fillings.

Cade took the first three bats as soon as they came off the line; two were in use during his travel ball season, the third – in his school colors – he’s saving. Another is in the hands of Lawson State player Kolby Brannon, who has used it in batting practice and games. Feedback so far has been positive.

In time they’d like to get one of their bats in the hands of Angels’ outfielder Todd Cunningham and Rays farmhand Coty Blanchard. Eventually they might even challenge the industry’s heavy hitters. There are currently about 30 companies approved to sell bats to major-league teams.

“I was joking with one of my friends and we were talk about the World Series,” Cade said. “I told him wouldn’t it be awesome if you looked at the World Series one year and saw a guy using a Cherokee County Bat.

“When we watch baseball on TV and see them using a bat we’d never heard of, you look it up (on the internet) and see they started like we did, a small thing and growing. I’m hoping ours will be that way, too.”

You must be logged in to post a comment Login